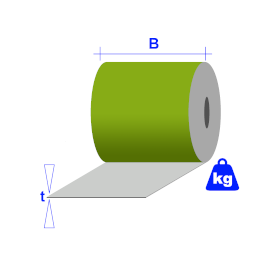

Coil

Results

Add this search to my alerts4 Products

| Material Number - alloy |

thickness (mm) - t |

min. width (mm) - B |

Location | Origin | Surface Type |

Total Quantity (kg) |

Min deliverable quantity (kg) - lot |

Price ▲ | |||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 2.4819 - C276 | 0.50 | 1000.00 | IN, 400004 | JP | 2B | 1800.00 | 300.00 | €52.00 / kg Negotiate |

1 lot(s)

Add to Cart

|

||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||

| 2.4819 - C276 | 0.25 | 610.00 | IN, 400004 | DE | 2R | 1000.00 | 200.00 | €64.00 / kg Negotiate |

1 lot(s)

Add to Cart

|

||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||

| 2.4819 - C276 | 0.20 | 610.00 | IN, 400004 | DE | 2R | 1000.00 | 100.00 | €65.50 / kg Negotiate |

1 lot(s)

Add to Cart

|

||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||

| 2.4819 - C276 | 0.20 | 500.00 | IN, 400004 | DE | unknown, see information | 800.00 | 50.00 | €81.00 / kg Negotiate |

1 lot(s)

Add to Cart

|

||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||

Alloy C276 / 2.4819

2.4819 has a very good resistance to pitting, crevice corrosion and stress corrosion cracking

Material Data Sheet

| Material Designation | 2.4819 |

| Alloy | Alloy C276 |

| EN Material Symbol | NiMo16Cr15W |

| UNS | N 10276 |

| Trademark | Nicrofer®5716hMoW |

| VdTÜV Data Sheet | 400 |

| DIN EN | DIN EN 17744 |

Main fields of application of alloy C276

AlloyC276 is often used in the chemical and petrochemical industries. The material is preferably used in cases where hot contaminated mineral acids, solutions and organic acids (such as acetic and formic acid) and seawater occur. Other areas of application include:

- Sulfuric acid cooler

- pulp and paper industry, for example for pulping and bleaching vessel

- Equipment and components for Sour Gas

- Washer and particular retrieval heater and fans for continuous wet combustion - flue gas and desulphurisation

- Reactors for the production of acetic acid

- Production and processing technology contaminated phosphoric acid

Chemical composition of alloy C276

| C | Si | Mn | P | S | Cr |

| % | ≤ % | ≤ % | ≤ % | ≤ % | % |

| 0.01 | 0.08 | 1.0 | 0.015 | 0.01 | 15.0-16.5 |

Characteristics of alloy C276

| Temperature Range | Material for wet corrosion |

| Density | 8.9 g/cm³ |

| Melting Range | 1325 – 1370°C |

| Elongation at break of Alloy 59 at room temperature: | 30 % |

| ≤ 5mm | 25 % |

| ≥ 5 - ≤ 25 mm | |

| ISO-V notch impact toughness at -59°C | ≥ 120 J/cm² at room temperature |

| ≥ 90 J/cm² |

Filler metal (for welding with alloy C276)

Material:

2.4607

Covered electrode:

Material

2.4609

2.4819

MIG/TIG