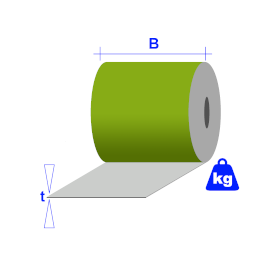

Coil

Results

Add this search to my alerts5 Products

| Material Number - alloy |

thickness (mm) - t |

min. width (mm) - B |

Location | Origin | Surface Type |

Total Quantity (kg) |

Min deliverable quantity (kg) - lot |

Price ▲ | |||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 2.4856 - 625 | 0.50 | 1250.00 | IN, 400004 | JP | 2B | 1700.00 | 1700.00 | €50.00 / kg Negotiate |

1 lot(s)

Add to Cart

|

||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||

| 2.4856 - 625 | 0.50 | 540.00 | IN, 400004 | FR | 2R | 1200.00 | 400.00 | €54.00 / kg Negotiate |

1 lot(s)

Add to Cart

|

||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||

| 2.4856 - 625 | 0.20 | 610.00 | IN, 400004 | FR | 2R | 1000.00 | 200.00 | €58.30 / kg Negotiate |

1 lot(s)

Add to Cart

|

||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||

| 2.4856 - 625 | 0.30 | 610.00 | IN, 400004 | FR | 2R | 400.00 | 100.00 | €61.30 / kg Negotiate |

1 lot(s)

Add to Cart

|

||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||

| 2.4856 - 625 | 0.05 | 506.00 | IN, 400004 | US | 2R | 20.00 | 20.00 | €110.00 / kg Negotiate |

1 lot(s)

Add to Cart

|

||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||

Alloy 625 / 2.4856

Alloy 625 is a low carbon (0.03%) nickel-chromium-molybdenum-niobium alloy which has excellent corrosion resistance to a wide range of corrosive media. Alloy 625 is normally supplied in annealed condition for wet corrosion applications and is TÜV-approved for pressure vessels in the temperature range from -196°C to 450°C. In annealed condition (grade 1) Alloy625 is characterized by:

Material Data Sheet

| Material Designation | 2.4856 |

| Alloy | Alloy 625 |

| EN Material Symbol | NiCr22Mo9Nb |

| UNS | N 06625 |

| VdTÜV Data Sheet | 499 |

Main fields of application of alloy 625

2.4856 is used for:

- Natural gas pipelines

- Production systems and pipe coverings of riser pipes in oil production

- Preparation of phosphoric acid

- Shipbuilding and marine water lines

- Plants for the treatment of radioactive waste

- Flue gas scrubbers and dampers in flue gas cleaning systems

Chemical composition of alloy 625

| C | Si | Mn | P | S | Cr | Mo |

| % | ≤ % | ≤ % | ≤ % | ≤ % | % | % |

| 0.03 | 0.4 | 0.5 | 0.01 | 0.01 | 21.0-23.0 | 8.0-10.0 |

Characteristics of alloy 625

| Temperature Range | Wet corrosion and high-temperature variant possible |

| Density | 8.44 g/cm³ |

| Melting Range | 1290°C - 1350°C |

| ISO-V notch impact toughness (average at room temperature acc. to DIN EN 10045 part 1) | lengthwise ≥ 125 J/cm² |

| across ≥ 100 J/cm² |

Filler metal (for welding with alloy 625)

Welding rods and wire electrodes:

Nicrofer S 6020 - FM 625 (2.4831)

DIN EN ISO 18274: S Ni 6625 (NiCr22Mo9Nb)

UNS N06625

AWS: 5.14: ErNiCrMo3

Covered electrodes:

DIN EN ISO 14172: E Ni 6625 (NiCr22Mo9Nb)

(2.4621)

UNS W86112

AWS A5.11: ENiCrMo-3