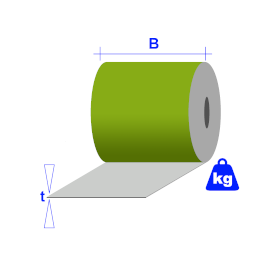

Coil

Results

Add this search to my alerts2 Products

| Material Number - alloy |

thickness (mm) - t |

min. width (mm) - B |

Location | Origin | Surface Type |

Total Quantity (kg) |

Min deliverable quantity (kg) - lot |

Price ▲ | |||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 2.4858 - 825 | 0.50 | 1250.00 | IN, 400004 | JP | 2B | 3000.00 | 300.00 | €25.00 / kg Negotiate |

1 lot(s)

Add to Cart

|

||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||

| 2.4858 - 825 | 0.20 | 5.00 | IN, 400004 | US | 2B | 1000.00 | 100.00 | €39.50 / kg Negotiate |

1 lot(s)

Add to Cart

|

||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||

Alloy 825 / 2.4858

Alloy 825 is a titanium-stabilized, fully austenitic nickel-iron-chromium alloy with additions of copper and molybdenum. Alloy 825 is characterized by:

Material Data Sheet

| Material Designation | 2.4858 |

| Alloy | Alloy 825 |

| EN Material Symbol | NiCr21Mo |

| UNS | N 08825 |

| VdTÜV Datasheet | 432/1 |

| ISO | NiFe30Cr21Mo3 |

Main fields of application of alloy 825

Typical examples for the use of 825 are as follows:

- chemical plants

- Air-cooled heat exchangers in LNG process (LPG)

- Heat exchangers, evaporators, scrubbers, fork tubes, in the phosphoric acid production

- Components in sulfuric acid pickling lines, such as heating coils, tanks, boilers, baskets and chains

- Fuel element for a variety of media, such as dissolver sulfuric and nitric acid, sodium hydroxide, etc., which are used in the recycling process

- Food preparation

- seawater-cooled heat exchangers, offshore pipelines, pipes and parts in natural gas operation

Chemical composition of alloy 825

| C | Si | Mn | P | S | Cr | Mo |

| % | ≤ % | ≤ % | ≤ % | ≤ % | % | % |

| 0.025 | 0.5 | 1.0 | 0.02 | 0.015 | 19.5-23.5 | 2.5-3.5 |

Characteristics of alloy 825

| Temperature Range | up to 550°C |

| Density | 8.1 g/cm³ |

| Melting Range | 1370°C – 1400°C |

| Elongation at break of Alloy 825 | 30 % |

| ISO-V notch impact toughness | ≥ 150 J/cm² at room temperature, lengthwise (only bars and forgings) |

| ≥ 100 J/cm² at room temperature, across |

Filler metal (for welding with alloy 825)

Alloy 825 can be welded by all conventional methods.

The following welding is recommended:

WIG/MIG2.4831

SG- NiCr21Mo9NbFilter Rod2.4621

EL- NiCr20Mo9Nb