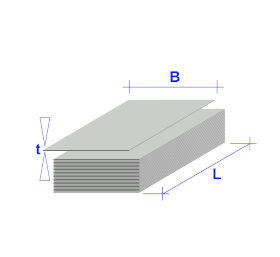

Sheets & plates

Results

Add this search to my alerts1 Products

| Material Number - alloy |

thickness (mm) - t |

min. width (mm) - B |

max. width (mm) - B |

min. length (mm) - L |

max. length (mm) - L |

Location | Origin | Surface Type |

Total Quantity (kg) |

Min deliverable quantity (kg) - lot |

Price ▲ | ||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1.4542 - 630 | 6.00 | 1000.00 | 2000.00 | DE, 24558 | DE | unknown, see information | 196.00 | 98.00 | €33.60 / kg Negotiate |

1 lot(s)

Add to Cart

|

|||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||

17-4 PH / 1.4542

17-4PH is a well-established precipitation hardening martensitic stainless steel capable of achieving very high strength and hardness after a relatively simple heat treatment. It offers excellent corrosion resistance combined with a structured range of mechanical property levels depending on the precise heat treatment applied.

Main fields of application of 1.4542

Surgical and dental instrument, screwdriver.

17- 4 retains a high strength of precipitation hardening stainless steels a majority of applications are within the aerospace sector and OAG applications

- Valves and engine components

- Turbine blades

- Gears

- Shafts

- Aircraft structures

Chemical composition of 1.4542

| Cr | 15,0 - 17,0 |

| Ni | 3,0-5,0 |

| Cu | 3,0-5,0 |

| C | max 0,070 |

Characteristics of 1.4542

| annealed | specification values |

| tensile strength Rm | 1000-1100 MPa |

| elongation A | 5 - 8 |

| Aged at 480 ⁰C | specification values |

| tensile strength Rm | 1150 – 1350 MPa |

| elongation A | 7 - 15 |

Heat treatment

Alloy 17-4PH is provided in the solution-annealed condition (Condition A). Mechanical properties may be improved by subsequent age hardening treatments. These aging treatments are commonly described as conditions H900, H1025, H1075, H1150, H1150M and H1150D.

Mechanical Properties

| Condition | UTS | 0.2% Yield | Elongation | Reduction of area | Hardness Brinel |

| H900 | 190.000 | 170.000 | 10 | 40 | 388 |

| H1025 | 155.000 | 145.000 | 12 | 45 | 331 |

| H1075 | 145.000 | 125.000 | 13 | 45 | 311 |

| H1150 | 135.000 | 105.000 | 16 | 50 | 277 |

| H1150m | 115.000 | 75.000 | 18 | 55 | 255 |

| H1150-D | 125.000 | 105.000 | 16 | 50 | 255 |