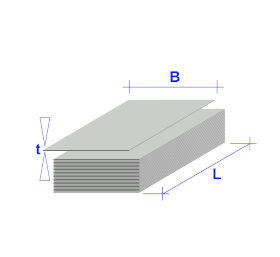

Sheets & plates

Results

Add this search to my alerts2 Products

| Material Number - alloy |

thickness (mm) - t |

min. width (mm) - B |

max. width (mm) - B |

min. length (mm) - L |

max. length (mm) - L |

Location | Origin | Surface Type |

Total Quantity (kg) |

Min deliverable quantity (kg) - lot |

Price ▲ | ||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 2.4816 - 600 | 1.50 | 1219.00 | 3048.00 | IN, 400 004 | US | unknown, see information | 1500.00 | 47.00 | €21.00 / kg Negotiate |

1 lot(s)

Add to Cart

|

|||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||

| 2.4816 - 600 | 3.00 | 2000.00 | 6000.00 | CZ, 15500 | DE | 1D | 1575.00 | 315.00 | €42.00 / kg Negotiate |

1 lot(s)

Add to Cart

|

|||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||

Alloy 600 / 2.4816

Alloy 600 is a nickel-chrome-iron alloy which is characterized by:

Material Data Sheet

| Material Designation | 2.4816 |

| Alloy | Alloy 600 |

| EN Material Symbol | NiCr15Fe |

| UNS | N 06600 |

| Trademark | Nicrofer® 7216 |

| ISO | NiCr15Fe8 |

| VdTÜV Data Sheet | 305 |

Main fields of application of alloy 600

Alloy600 is versatile. Some Applications of Alloy 600 are:

- Furnace casing seals, fans and fittings - stable in furnace atmospheres

- vessels and heat exchanger tubes in the production of vinyl chloride

- components for the preparation of chlorinated and fluorinated hydrocarbons

- Tubes for pyrolysis-dichloroethylene – resistant to carburization, chlorine, hydrogen chloride and oxidation

- Production of caustic alkalis, particularly with existence of sulfur compounds

. In nuclear reactors for parts such as ducts for control rods, reactor vessels and seals, steam dryers and separators in boiling water reactors

- Transport rollers, nozzles and other fittings in industrial furnaces

- Metamorphosis from uranium oxide to tetrafluoride by hydrofluoric acid – stable against hydrofluoric acid

- Thermocouple Protection Tubes – resistant to carburizing and nitriding atmosphere

Chemical composition of alloy 600

| C | Si | Mn | P | S | Cr |

| ≤ % | ≤ % | ≤ % | ≤ % | ≤ % | % |

| 0.05-0.1 | 0.5 | 1.0 | 0.02 | 0.015 | 14.0-17.0 |

Characteristics of alloy 600

| Temperature Range | Due to its higher creep rupture strength, Alloy 600 can also be used for temperatures above 700 ° C |

| Density | 8,42 g/cm³ |

| Melting Rage | 1370°C – 1425°C |

| Elongation at break of Alloy 600 sheet at 20 ° C | 30 % |

| ISO-V notch impact toughness at room temp. | across ≥ 150 J/cm², lengthwise ≥ 200 J/cm² |

| Forgings | across ≥ 120 J/cm² |

Filler metal (for welding with alloy 600)

Alloy 600 can be welded using covered electrodes by all conventional processes such as TIG, MIG pulse technology, manual arc welding. For TIG and MIG welding an addition type 2.4806 and a coated electrode to the appropriate type 2.4648 should be used. Moreover 2.4620 serves as filler material for 2.4816.